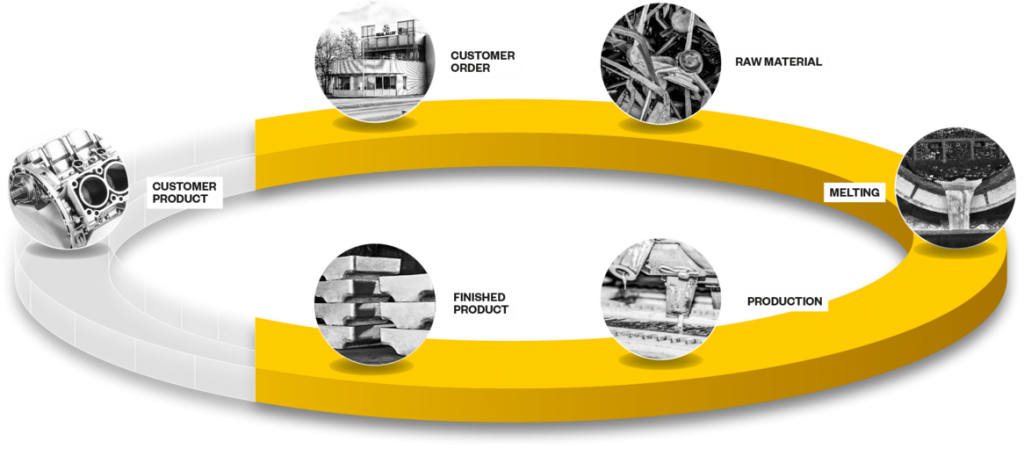

Aluminum is infinitely recyclable. It remains essentially unchanged no matter how many times it is processed and used. Therefore, it can be considered as a material with permanent characteristics, one that is not consumed, but used over and over again, without the loss of its essential properties. And, as the energy required for aluminum’s primary manufacture is locked inside the metal, only a fraction, just 5%, of that original power is needed to drive the recycling process. It is as if the energy is ‘banked’ for the future. In addition, an equal amount of greenhouse gas equivalents is saved each time an aluminum product is recycled at the end of its life, regardless of whether it was a beverage can, a car or part of a building. But not everything is as bright as the material itself. Aluminum recycling depends on there being enough aluminum scrap for smelting and Refining. So we need to implement a series of activities to generate more scrap, and optimize its availability for Euro, Asia and specially in Sultanate of Oman businesses, for example by improving the collection and treatment of used aluminum. We live in a world of volatile energy prices. There is concern over energy security and dependency. Support for increased accessibility of aluminum scrap, Sultanate of Oman “energy bank”, promises tangible benefits for the territories climate, energy and resource efficiency ambitions. The goal is to build on Sultanate of Oman reputation as a recycling community and deliver a sustainable business whose contribution to our large, diverse and circular economy will stretch far into the future.

Typical input material of the furnace & procedure: Soft and Hard aluminum material, clean as well as contaminated material like: SHEETS, BLANKS, PROFILES, CASTINGS PARTS, TENSE, FOILS, USED BEVERAGE CANS (UBC), And etc.

Aluminum Alloys Product:

The output material will be aluminum alloys as per international standard analyzes.

Collection of Scrap:

While the term ‘scrap’ might imply something of little value, to aluminum recyclers it means the exact opposite. It represents the vital raw material of their thriving and growing industry. The scrap value of used aluminum is normally high enough to compensate for the investments made in modern waste collection and sorting equipment.

Aluminum: The recycling phenomenon where Sultanate of Oman aluminum scrap is recycled Source:

First there is the metal harvested either during the primary aluminum production or at any of the processes leading to final fabrication. Then there is the scrap recovered from products containing aluminum that have reached the end of their service life.

While this is an encouraging picture, things become more challenging once products are either discarded or come to the end of their life-cycle. This aspect of the yield depends very much on initial product design concepts which embed recycling principles for end-of life. But it also relies on initiatives to collect aluminum for recycling. This means citizens, industry, municipal and national authorities all participating in efficient and innovative collection systems.

For example, local schemes to collect used beverage cans play an important role. By releasing the high scrap value of aluminum, they can generate substantial income for municipalities, waste management companies and even individual collectors. In fact, based on its population, Asia, US and Europe is the world’s greatest per capita recycler.

Soring and Treatment :

Once scrap has been collected, the process of preparing it for recycling can begin. Scrap is treated according to its origin or previous use. This is a highly technical part of the process. The versatility of aluminum means a vast array of different applications, each with its own physical properties and alloys that demand specific treatment. Whether a window, the engine block of a car or an electrical component, they all need to be processed into their various constituent parts so that the aluminum elements can be separated.

Aluminum preserves its core properties through infinite cycles of use. It can be recycled ready for fabrication either into the same product as before without any loss of quality (‘closed aluminum product loop’) or into something completely different. Our recycling industry consists of closed loop recycling for certain products.

End User Products:

From recycling to our standard aluminum alloys and finally to the End User Products.

Procedures: Once treatment is complete, the recovered aluminum has to be recycled by being smelted or refined. Refiners produce casting alloys and smelters generate wrought alloys for sheets, strips and extrusions and etc.

This results in new raw material for a wide variety of applications. For example, refined aluminum can be found in cast engine blocks, while smelted aluminum will be used for products like car bodies or beverage cans.

Jabal Al Shams Industrial Services LLC (JAS) an Excellent grade company, as a JSRS approved local manufacturer has been formed from a highly educated and experienced team with more than 30 years’ experience in the field of Petroleum and Aluminum Industry. We have been certified by TUV International to different ISO standards.