It is only 160 years since the element aluminium was discovered and only 100 years since a viable production process was established, and today more aluminium is produced each year than all other non-ferrous metals combined.

Aluminium is the third most abundant element – comprising some 8 percent of the earth’s crust. So, why was it not discovered sooner? The main reason is that aluminium never occurs naturally in metallic form. Aluminium is found in most rocks, clay, soil and vegetation combined with oxygen and other elements.

Aluminium bearing compounds have been used by man from the earliest times, pottery was made from clays rich in hydrated silicate of aluminium. Ancient Middle Eastern civilisations used aluminium salts for the preparation of dyes and medicines: they are used to this day in indigestion tablets and toothpaste. At one point in history, aluminium was such a valuable commodity that rulers and the wealthy preferred impressing their guests with plates and cutlery made from aluminium rather than gold.

The English chemist Sir Humphrey Davy underlined the existence of the element arguing that “alum” was the salt of an unknown metal which he said should be called ‘alumium’. The name was respelt as the more pleasant sounding ‘aluminium’ by later scientists. Davy tried unsuccessfully to produce aluminium by electrolysing a fused mixture of aluminium oxide and potash.

Following Davy’s work the Danish physicist H.C. Oersted managed to produce the first nodules of aluminium by heating potassium amalgam with aluminium.

Friedrich Wöhler in Germany established many of the metal’s properties, including the remarkable lightness. It was the discovery of this property that truly excited researchers and paved the way for more generous development funding.

The Frenchman Henri Sainte-Claire Deville developed a reduction process using sodium which, with further refinement by others, allowed the production of high cost metal in limited quantities and his process was copied throughout Europe. Scientists were now in the position to produce kilograms rather than mere grams – an important step towards the industrial use of aluminium.

The smelting process that is still used today was discovered almost simultaneously but independently in the United States and France. Working in a woodshed in Ohio, Charles Martin Hall made the same discovery that metallurgist Paul Lois Toussaint Héroult made in a makeshift laboratory in Gentilly: both men dissolved aluminium oxide in molten cryolite and then extracted the aluminium by electrolysis.

Hall filed patents in the USA and Héroult in France but Hall was eventually credited with being the earlier inventor due to the slightly earlier patent application that he made.

The success of the Hall/Héroult process was advanced when Karl Bayer, an Austrian, invented an improved process for making aluminium oxide from bauxite. These inventions sealed the fate of aluminium – by 1890 the cost of aluminium had tumbled some 80 percent from Deville’s prices. The metal was now a commercial commodity, how would it be used?

The discovery, successful extraction and the first commercial applications of aluminium all took place in the 19th Century. The enthusiasm for new materials and their possible uses was immense. The general urge to discover did not only affect metals – the first organic plastics were made in the 1870’s. Rubber and plywood industries were also established during the same period.

The general public was also intrigued. Charles Dickens (Household Words, Dec. 13th 1856) commenting on Deville’s initial success wrote: “Aluminium may probably send tin to the right about face, drive copper saucepans into penal servitude, and blow up German-silver sky-high into nothing”.

When Jules Verne wrote “From the Earth to the Moon” (1865) about the fictitious first attempt to send man to the moon, the material he chose to “build” his space capsule was aluminium – the one material with the lightness and strength for such a project.

Some 15 years later J.W. Richards wrote in his standard work “Aluminium” that: “It has been well said that if the problem of aerial flight is ever to be solved, aluminium will be the chief agent in its solution”.

Despite all the excitement and scientific successes, the pioneers quickly found that, once viable production was established, selling the output was very difficult indeed. Markets did not exist and had to be developed from scratch and the manufacturing industry, used to more traditional metals, needed to acquire specific skills to successfully fabricate aluminium end products. During the period between 1855 and 1900 many aluminium manufacturing businesses were established, most prospered briefly and rapidly waned. Only a select few survived into the 20th Century.

The first target markets involved the substitution of copper, brass and bronze. Despite the initial difficulties, world production of aluminium soared from less than 200 tonnes in 1885 to approximately 22 million tonnes in 1998 – plus some 5 million tonnes of recycled aluminium. The prophecies of Dickens, Verne and Richards have come true!

Discovery of aluminum

Humankind came across aluminium long before the metal we know today was produced. The Natural History by Pliny the Elder, a Roman scientist, told the story of a first century craftsman presenting a cup made of an unknown metal looking like silver, but too light to be sliver, to Tiberius, the Roman Emperor.

Alum, an aluminium-based salt, was used extensively in ancient times. Commander Archelaus discovered that wood was practically flame resistant if it was treated using an alum solution; protecting his wooden fortifications against flamed attack. Alum was used throughout Europe from the XVI century onwards: in the leather industry as a tanning agent, in the paper-pulp industry for paper sizing and in medicine, i.e. dermatology, cosmetology, stomatology and ophthalmology.

Aluminium was named after alum, which is called ‘alumen’ in Latin. This name was given by Humphry Davy, an English chemist, who, in 1808, discovered that aluminium could be produced by electrolytic reduction from alumina (aluminium oxide), but did not manage to prove the theory in practice.

1777 — 1851

Hans Christian Oersted from Denmark was successful in 1825; however he apparently produced an aluminium alloy with the elements used in the experiments, rather than pure aluminium.

Hans Christian’s work was continued by Friedrich Woehler, a German chemist, who set about working from 30 grams of aluminium powder in October 22, 1827. It took another 18 years of continuous experimentation for Friedrich to create small balls of solidified molten aluminium (globules) in 1845.

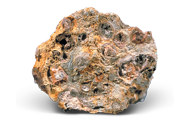

Discovery of aluminium ore. In 1821 Geologist Pierre Berthier discovered reddish clay rock deposits. The rock was named bauxite after Les Baux area where it was found.

Henri-Etienne Sainte-Claire Deville, an outstanding French chemist and technologist, transferred the chemical method of aluminium creation discovered by scientists to industrial application. He improved the Woehler process and produced the first industrial aluminium together with his partners at Charles and Alexandre Tissier’s production facility in Rouen (France) in 1856.

of metal were produced in 36 years (1855-1890) when the chemical method developed by Sainte-Claire Deville was applied

The produced metal resembled silver, it was light and expensive, hence at that time aluminium was considered an elite material intended for ornaments and luxury items. The first aluminium products are considered to be medals made during Napoleon III’s reign. Napoleon supported the development of aluminium production and Friedrich Woehler designed a rattle for Crown Prince Louis Napoleon made of aluminium and gold.

However, even then Sainte-Claire Deville understood that the future of aluminium was not just to be associated with jewellery:

Sainte-Claire Deville

French chemist

Hall-Héroult process

Aluminium’s development changed with the discovery of a more cost-efficient electrolytic production method in 1886. It was developed by Paul Héroult, a French engineer, and Charles Hall, an American student, independently and at the same time. The method involved the reduction of molten aluminium oxide in cryolite. The process demonstrated excellent results, but required an enormous amount of electric power.

Paul Héroult

Charles Hall

1863-1914

1863-1914

Héroult avoided this problem by harnessing the power of the Rhenish Falls in Neuhausen (Switzerland) where the force of the falling water bought the smelters dynamos into operation.

The Swiss Metallurgical Society and Rathenau, a German industrialist, signed an agreement establishing the Aluminium Industry Joint Stock Company with the total value of CHF 10 million in Neuhausen on November 18, 1888. Later it was renamed to the Aluminium Smelter Society and its logo depicted the sun rising from beyond an aluminium ingot. Rathenau’s idea was that it should symbolise the dawn of the aluminium industry. Following the Aluminium Smelter Society’s creation aluminium production efficiency increased more than 10 times in five years. Just 40 tonnes of aluminium were melted in 1890 in Neuhausen compared with 450 tonnes in 1895.

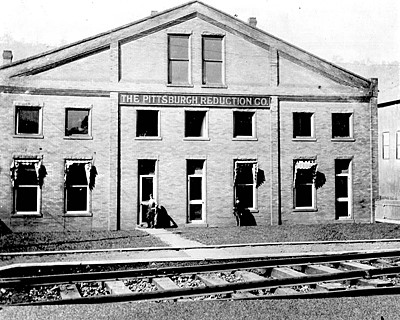

Charles Hall, with the support of his friends, established the Pittsburgh Reduction Company which launched its first smelter in Kensington outside Pittsburgh on September18, 1888. It produced only 20-25 kg of aluminium per day in the first few months, but quickly accelerated to 240 kg daily by 1890

The Pittsburgh Reduction Company built new smelters in New York State near the new Niagara hydroelectric power station. Smelters are historically built in the vicinity of powerful, cheap and environmentally friendly energy sources, such as hydroelectric power stations, even today. The Pittsburgh Reduction Company was reorganised into the Aluminium Company of America, or more commonly known, Alcoa in 1907.

Karl Joseph Bayer, an Austrian chemist, invented a cheap and feasible alumina (aluminium oxide) production method in 1889 when working in St. Petersburg (Russia) at the Tentelevsky production facility. Going forward, Alumina became the basic raw material for aluminium production. The scientist added bauxite into an alkali solution and heated it in a closed vessel finding that the bauxite dissolved but not completely. Bayer did not find aluminium in the undissolved remains; however he found that entirety of the aluminium in the bauxite was transferred to the alkali solution during the process.

Aluminium production processes used today are based on the Bayer and Hall-Héroult processes.

The aluminium industry was created over several decades. The story of the ‘clay silver’ came to an end and aluminium became a new industrial metal.

Aluminium began to be used in various ways at the turn of the XIX and XX centuries which created an incentive for development in a new range of industries.

Alfred Nobel ordered the creation of Le Migron, the first passenger boat to use an aluminium hull, in Switzerland, 1891. Three years later the Scottish shipbuilding yard Yarrow & Co created a 58 metre torpedo boat made of aluminium named Sokol. Sokol was made for the Russian Empire’s Navy and accelerated to a speed of 32 knots, a record speed for the time.

In 1894 in New Haven, New York, Hartford Railroad, the American rail company then owned by banker John Pierpont Morgan (J.P. Morgan), started to produce special lightweight passenger railroad cars with aluminium seats. Just 5 years later, Karl Benz presented the first sports car with an aluminium body at an exhibition in Berlin.

Aluminium statue of Anteros, an Ancient Greek god, appearing in Piccadilly Circus, London, in 1893. At almost two and a half metres high, the statue became the first large piece of art made from aluminium. Several decades earlier, a fireplace clock or figurines in offices were believed to be a piece of luxury available only for high society.

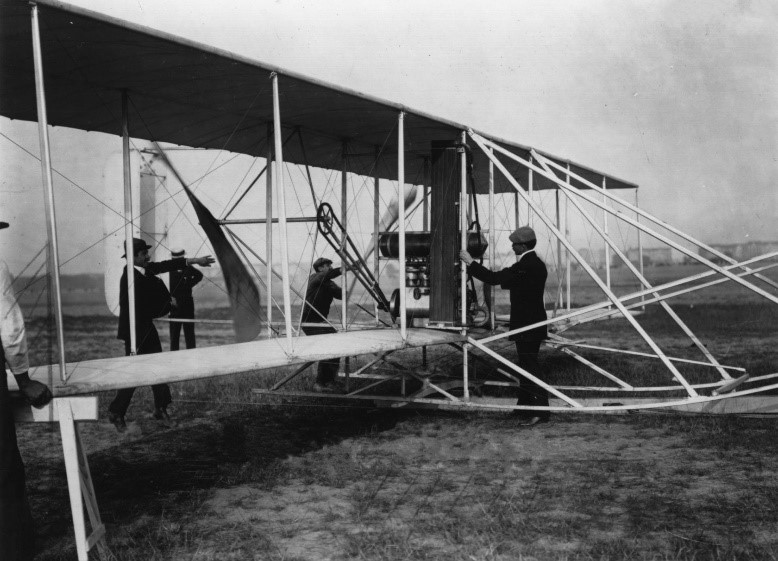

Still, aluminium used for aviation was the real revolution, which is where the name ‘winged metal’ was born. Inventors and aviators around the world work towards the development of controlled aerial vehicles during this period.

On December 17, 1903, Wilbur and Orville Wright, American aircraft designers, flew a controlled aerial vehicle, the Flyer-1, for the first time in human history. They originally tried to use a car engine to propel the aeroplane, but it turned out to be too heavy. Therefore, a completely new engine with aluminium parts was developed specially for the Flyer-1. A light, 13-hp motor made allowed the first ever plane to become airborne with Orville Wright at the helm for 12 seconds, flying 36.5 metres. The brothers performed another two flights, 52 and 60 metres, at a height of about 3 metres above ground level.

Duralumin, a key aluminium alloy, was invented in 1909. It took seven years for Alfred Wilm, a German scientist, to create it, but it was worth the years of effort. Duralumin, with addition of copper, magnesium and manganese was as lightweight, as aluminium, but significantly exceeded it in strength, hardness and elasticity meaning it quickly became the main material used in aviation. The hull of the first all-metal plane, the Junkers J1, developed in 1915 by a world aircraft industry pioneer, the famous German aircraft designer Hugo Junkers, was made from Duralumin

When the world entered a period of war, aviation played a crucial and sometimes decisive part. As duralumin was used in military technology initially, its production method was classified.

Meanwhile, aluminium gained uses elsewhere. Aluminium began to be used for the mass production of houseware that quickly and almost completely replaced copper and cast iron utensils. Aluminium frying pans and saucepans are light, warm and cool quickly and do not rust.

Robert Victor Neher invented the method used for continuous aluminium rolling foil production in Switzerland in 1907. He launched the world’s first foil rolling mill in 1910. A year later Tobler started to use foil for chocolate packing, still used to this day, even the famous Toblerone bar is wrapped in it too!

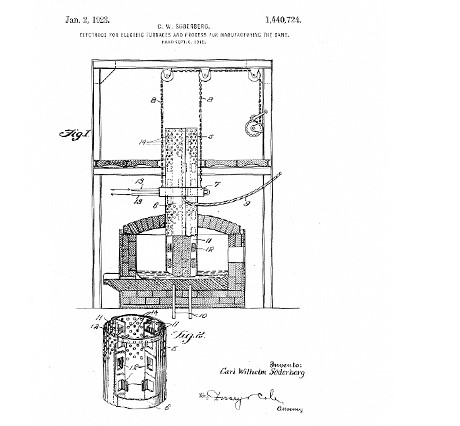

Another critical moment for the aluminium industry began in 1920, when a group of scientists under the leadership of Soderberg from Norway invented a new aluminium production process that made the Hall- Héroult method much cheaper. Previously, pre-baked coal blocks were used as anode cells during reduction; they were consumed quickly and so the use of new ones was required constantly. Soderberg solved this problem with the help of a continuous electrode. It is formed in a special reduction chamber from a coke and tar paste and added to the upper hole of the electrolyte cell when required.

The Soderberg process was quickly adapted in aluminium production throughout the world and resulted in output increase. The USSR had no aluminium industry at that time and added this to its armoury.

Thereafter, the application of electrolyte cells with pre-baked anode cells became more preferable due to the lack of resin emissions and lower power consumption. In addition, one of the main advantages of electrolytic cells with pre-baked anode cells was the possibility to increase amperage and therefore capacity.

Thereafter, the application of electrolyte cells with pre-baked anode cells became more preferable due to the lack of resin emissions and lower power consumption. In addition, one of the main advantages of electrolytic cells with pre-baked anode cells was the possibility to increase amperage and therefore capacity.

Aluminium was widely used in the aviation, shipbuilding and automotive industries during that time and started its progress in civil engineering. The Empire State Building, which was the highest building worldwide until 1970, was built in 1931. It was the first building where aluminium was widely employed in construction, both in the basic structures and in the interior.

The aluminium can, an iconic product that became one of the largest aluminium commodities, the symbol of environmental friendliness and a focal point in the field of art and design, emerged in the USA in 1958. The cans invention was shared between Kaiser Aluminium and Coors. Coors was not only the first company to sell beer in aluminium cans but also organised the collection of empty cans using a recycling system. Coca-Cola and Pepsi started to sell their drinks in aluminium cans in 1967.

In 1962, the legendary race car driver Mickey Thompson and his race car the ‘Harvey Aluminium Special’ made from aluminium alloys became a sensation at the Indianapolis 500. Despite the fact that his car has 70 HP less power than his competitors, Thompson came eighth in the qualification and ninth in the race. As a result, his team got the Mechanical Achievement Award for breakthrough in race car design.

Aluminium was the key material used in Shinkansen, the famous high-speed train and prototype of all modern trains of that type. Modern high speed trains were launched in Japan two years later. The train ran between Tokyo and Osaka and travelled 515 km in 3 hours and 10 minutes, a top speed of 210 km/hour.

Jabal Al Shams Industrial Services LLC (JAS) an Excellent grade company, as a JSRS approved local manufacturer has been formed from a highly educated and experienced team with more than 30 years’ experience in the field of Petroleum and Aluminum Industry. We have been certified by TUV International to different ISO standards.