Production procedure QC is responsible for sampling the melt several times to ensure that combination and homogenized of elements done correctly, then after final result received by quantometer test as well as density test of product accurate of the chemical composition acceptance. Also after ultimately quality control manager acceptance in order to be ensure that the analysis of the melt is in the range of demand, meanwhile product will be ready for casting and delivery to store.

Production of Aluminum alloys:

Aluminum alloys Production consist of two categories of raw material.

Raw Materials (Primary- Secondary)

1- Primary:

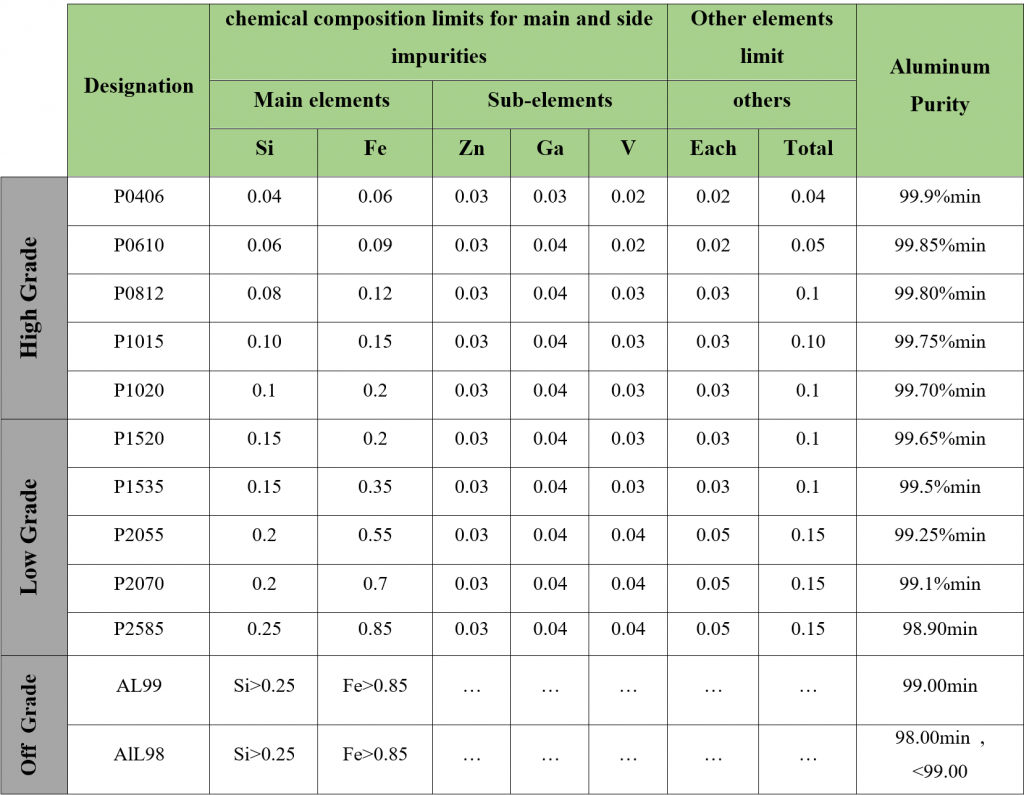

The pure aluminum from min 98.0% – Max 99.85%

2- Secondary:

Used Aluminium: like automotive parts, packing, Power lines, Building, profile, home appliance, Telecommunications and etc.…

JABAL-AL SHAMS – Aluminum Production:

Aluminum alloys is produced in two forms:

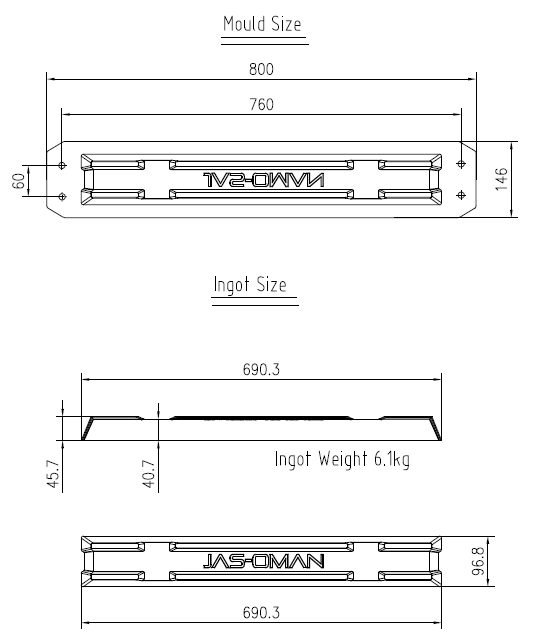

1- Aluminum alloys Ingots – standard sizes/ weigh about 6 kg.

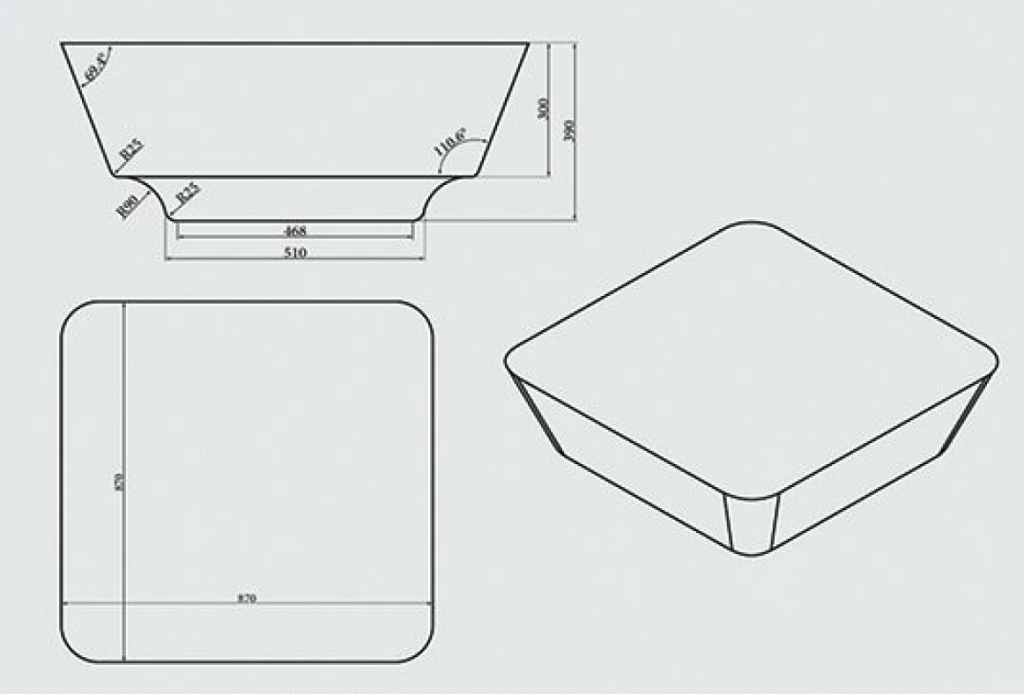

2- Aluminum alloys or Re-melted 1000 pound – standard sizes/ weigh 1000 -pound sows.

QC is responsible for sampling the melt several times to ensure that combination and homogenized of elements done correctly, then after final result received by quantometer test as well as density test of product accurate of the chemical composition acceptance. Also after ultimately quality control manager acceptance in order to be ensure that the analysis of the melt is in the range of demand, meanwhile product will be ready for casting and delivery to store.

Each ingot weight about 6 kg

Each sow weight between 450-550kg

Jabal Al Shams Industrial Services LLC (JAS) an Excellent grade company, as a JSRS approved local manufacturer has been formed from a highly educated and experienced team with more than 30 years’ experience in the field of Petroleum and Aluminum Industry. We have been certified by TUV International to different ISO standards.